We recognize that selling flooring is a challenging task. There are so many types, styles, materials, colors, and patterns, that it can be a bit overwhelming. Hardwood. Carpet. Vinyl.RUBBER. Cork. Tile. And what exactly is LVT?

We’re here to help. Drawing on our 80+ year experience designing, manufacturing and selling flooring of all different types, we’ve put together this guide to try to help you help your customers make the decision that best suits their home or project.

We’ve put together a very brief overview of the different flooring options, some of the pros and cons and a little more detail to help you answer questions from your customers.

This is certainly not a deep dive into flooring options – but it will give you a broad overview of the different options available. And hopefully you’ll come back to this site from time to time to learn more detail about the latest products, colors and trends in flooring.

Happy selling!

HARDWOOD FLOORS

Solid vs. Engineered

“Engineered” refers to the floors being constructed of multiple layers of real wood as opposed to a single “solid” piece of wood. Engineered floors have a “wear layer” which is the top layer of hardwood (the wood you see and stand on) and a “base layer” which can be a single or multilayer of different wood.

Engineered floors are more stable (they expand and shrink less then solid floors due to humidity changes) making them the primary choice for flooring that exceeds 5” in plank width. The lifespan of both types of floors, including how many times the floor can be sanded down and refinished is defined by the floors overall thickness.

Pre-finished vs. Unfinished

All hardwood floors have a finish applied to the top surface of the wood to both protect the floor and give it a desired appearance. In “prefinished” flooring, the finish is applied when the floor is manufactured, requiring no additional finishing once installed.

“Unfinished Floors” are manufactured without the finish. Once they are installed, the installer will sand and then “finish” the floors. With prefinished floors you can see exactly what you are getting while unfinished flooring are a blank canvas from which the installer can create a custom finish.

COMPOSITE/RIGID FLOORS

While LVT flooring (Luxury Vinyl Tile) flooring is extremely popular and versatile, as technology improves and advancements are made within the vinyl flooring segment, a new technology has emerged that improves upon key benefits like waterproof, scratchproof and dent proof (did somebody say great for kids and pets?!)

This new category is the fastest growing segment in flooring, and is sometimes referred to as “rigid”, “SPC” or “WPC”. Regardless of names, it continues to evolve as new technology elevates the quality of the appearance and resiliency of the flooring within this category.

The key benefits that have been improved are:

Waterproof: Allows it to be used in areas unsuitable for hardwood floors or carpets

Resistant to dents and scratches: A popular attribute for areas expected to endure rugged use. Take a look at the “dent test” video below

Minimal Expansion: Requiring less environmental consistency then natural flooring (for example, its great if you live in an area with a great deal of humidity or in a dry area – the floor won’t expand or shrink like other materials)

Looks like wood or stone: The style options continue to grow as the technology allows the floor to replicated wood or stone

Technology Overview — GemCore Stone Composite Flooring

Here is an example of our category leading GemCore line of flooring to give you a little more detailed information:

1. Quartz Enhanced Acrylic Coating. Mineral-enhanced finish provides an extreme layer of durability proven to resist shoe scuffs, kids toys and even pet claw marks!

2. Decorative Layer. Combines state-of-the-art print and emboss technology for the look and feel of natural wood. In selected collections, we offer *EIR "Embossed In Register" technology that aligns the texture and printing for a more realistic wood appearance.

3. Substrate Made with over 70% stone. GemCore™ is more stable and more dent resistant than WPC, LVT and laminate!

4. Anti-Microbial Pre-attached Backing.The pre-attached non-toxic underlayment pad makes installation fast and easy, with enhanced sound performance.

LUXURY VINYL TILE

You may have heard of “LVT” flooring (Luxury Vinyl Tile) and for a good reason – this is an extremely popular and growing segment of flooring as it meets the needs of many homeowner and business owners.

LVT flooring is extremely versatile, as it provides a beautiful flooring option at a more economical price. And best of all, it looks like real wood!

LVT flooring is made from multi-layer synthetic materials fused together with a lamination process. In most cases, its designed to look like natural wood. This is achieved by printing an extremely high quality and detailed image of a particular wood type onto the tile plank, before applying a clear protective layer that helps prevent against liquids and scratches. It’s extremely durable and easier to maintain than traditional hardwood.

TECHNOLOGY OVERVIEW — GEMCORE LUXURY VINYL TILE

1. Anti-Microbial Wear Layer with Polyurethane Ceramic Bead or Quartz-Enhanced finish. Extreme durability proven to resist shoe scuffs, kids toys and even pet claw marks!

2. Decorative Layer. Combines state-of-the-art print and emboss technology for the look and feel of natural wood. In selected collections, we offer *EIR "Embossed In Register" technology that aligns the texture and printing for a more realistic wood appearance.

3. Base Layer. 100% Virgin Vinyl OPF (Ortho Phthalate Free) offers superior performance without the risks of heavy metals or other contaminates found in recycled vinyl.

GEMCORE ADVANTAGES

Our team of designers and engineers focuses on the details to bring you the very best in LVT:

• Subtle embossing creates desired texture without clouding the appearance of the surface

• On trend colors and patterns

• 100% Virgin (contaminant free) material

• Extra wide (10") luxury plank options

PORCELAIN/CERAMIC TILE

Clay-base ceramic tiles are extremely hard and durable, making them popular choices for kitchens, baths, basements, and other moisture-prone areas. From classic rectangular shapes to dramatic shapes and pattern offered in a myriad of different colors and surface textures, the range of options in this category are staggering.

Ceramic floor tiles are installed by adhering the tiles to a well-constructed substrate before grouting the edges to create a waterproof seal. They are considered one of the most durable and wear resistant flooring options and are relatively easy to care for with exception regarding some extra maintenance required to maintain the grouts appearance.

STONE/CONCRETE

Natural Stone

Natural stone is generally a more expensive option, but it remains a popular material for flooring due to its unique “no-two-pieces-look-alike” character and the diverse range of stone types and finished looks offered. Natural stone is sourced throughout the world and tile designs cover the gamut, from classic tiles built from some of the most accessible stone to premier designs sourced from exclusive quarries in exotic locales.

Like ceramics, natural stone tiles are installed by adhering the tiles to a well constructed substrate before grouting the edges to create a waterproof seal. Common natural stone categories include Marble, Travertine, Granite, Slate and Limestone. These names reflect the molecule makeup of the stone, but more importantly as relates to flooring, reflect what type of surfaces the stone can be offered in and the tiles relative durability and resiliency. These attributes can vary dramatically between stone types and even within each type making it integral to only utilize natural stone tiles that have been designated as appropriate for the intend area.

Concrete

Unique techniques have extended the finished looks achievable on a concrete floor, broadening the appeal of this relatively new consideration for interior flooring. Concrete floors are extremely hard and durable and if smooth, are easily maintained. Skilled installers can create unique color, textures and even patterns that are sometimes reminiscent of natural stone.

CARPET

The softest of common flooring materials, carpet remains popular for the distinct designs, feel and warmth it can provide a room. Often installed with a pad that offers additional cushioning, carpet also provides sound dampening. The most common types of carpet are made from either nylon, polyester, olefin or wool, each material offering a unique balance between look, feel and durability. Built using diverse manufacturing methods, carpets come in virtually any color and pattern one can imagine.

QUESTIONS YOU MAY BE ASKED

We’re sure you’ll find different levels of flooring knowledge among your different customers. This makes sense as some customers are further down the path and have done more research about flooring. While others may be visiting your store for the first time.

To help you through this process, we’ve compiled a list of some of the questions you might get, and some answers to help your customers understand the process. We hope this helps you during your sales process.

We’ve focused primarily on hardwood questions, as this is the most common (and sometimes most complicated) flooring category for your customers.

Can I put hardwood floors anywhere in my home?

Todays hardwood flooring is finished with state of the art surface protection in order to help protect the floors against aggressive use. In your home, you can use hardwood floors in virtually every room with living rooms, dining rooms, bedrooms, kitchens and hallways being the most popular locations to install hardwood flooring. Areas that may experience excessive moisture such as bathrooms, laundry rooms and below ground basements may not be appropriate. Homes in areas that experience dramatic changes in environmental conditions may also not be appropriate for certain types of hardwood floors. Hardwood floors used in areas that experience aggressive traffic (kids, pets, etc.) will naturally wear at a faster rate requiring refinishing sooner than floors used in low impact environments.

Can I install hardwood floors myself?

Hardwood flooring is almost exclusively installed by professional installers. There are many decisions during the installation of hardwood floors that can dramatically impact the success. Professional installers will first evaluate a project location in order to provide you a clear understanding of what floors are (or are not) appropriate for your project. They can often help you pick appropriate floors as well. Once you have chosen your floor, your installer will make crucial decisions on how to install your floors to meet your expectations. During installation the experience and craftsmanship of the installer will a defining factor in the quality of the final installed floor. We do not recommend installing hardwood flooring on your own.

How do I get my floors installed?

Many retail flooring locations may also offer installation along with the flooring. Does yours? If not, you can recommend a local flooring installer to install the material the customer purchased.

Often, the installer will work with the retailer to facilitate a seamless process. Seeing (and feeling) first hand the floors the customer intend to purchase is a crucial step in making an educated decision. Many companies allow customers to order samples directly from their website in addition to the retailer displays in your store.

How much will my wood floor cost including installation?

Hardwood flooring cost are broken out into material costs and installation costs. Material cost for flooring can vary dramatically based on the flooring you choose. While hardwood flooring starts as low as $3 per square foot, you can expect to pay $8-12 for premier quality floors. Installation costs are location and project specific, requiring an installer to come to your home to review the area and offer you an estimate with quotes commonly falling in between $3-9 per square foot.

Of course, each job is different and final cost depends on many factors. The installer will be best suited to calculate installation costs.

How long do hardwood floors last?

For most, a hardwood flooring decision happens once in a lifetime either as part of the process of building a new home or remodel. Quality hardwood flooring is designed to last the lifetime of the home if properly maintained. A reasonable expectation for when to refinish a hardwood floor (sanding off the surface layer and recoating) is 8-12 year, though aggressive use, including kids and pets can move up this timeline. Many folks may never choose to recoat or replace their hardwood floors over the entire time they live in their home. Hardwood flooring thickness plays an integral role in both the feel and longevity of a floor. Thicker floors provide a more solid feel underfoot and allow for refinishing a greater number of times, increasing the overall lifespan of the flooring.

How do I find the right looking wood floor for my project?

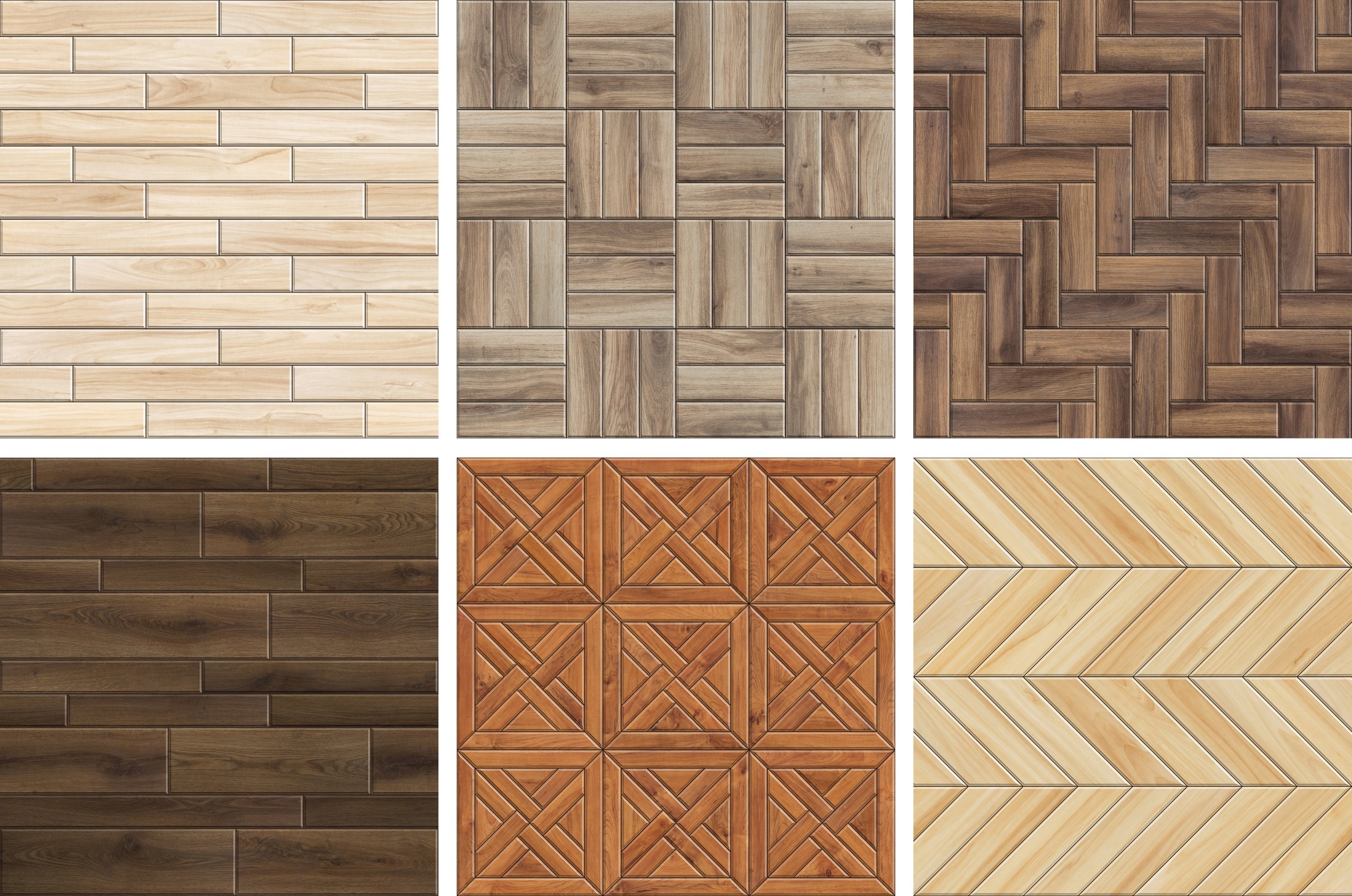

The final appearance and feel of your floor is a reflection of a species natural attributes, enhanced through a series of steps in the manufacturing of the flooring. The distinct appearance of a prefinished hardwood floor can be broken out into 7 key attributes that work in unison to create the final appearance. Learn the basics about each of these attributes below or click on the links to get detailed explanations for each.

MORE WOOD FLOORING SPECIFICS

Species

Each of type of wood offers different attributes, and selecting the right species involves weighing pros and cons across various characteristics, including appearance, stability, hardness, and cost. In hardwood flooring the species is your blank canvas from which all the following attributes build upon. The most common species used in hardwood flooring include Oak, Walnut, Hickory, Cherry, Maple and Birch along with a myriad of other domestic and exotic options for specific details on popular species click below

Grade & Cut

All lumber (wood) contains character markings including knots, mineral streaks and other naturally occurring irregularities. Selection, commonly referred to as “grade” describes how significant the amount of character markings appear in a given floor. Manufacturers may choose to utilize all material or be selective in order to achieve a certain grade. How a log is cut into flooring will also affect the surface appearance. For common grade and cuts please click below

Texture

After decades of the dominant popularity of glossy, texture free flooring, there has been a dramatic shift back to demand for hardwood floors with distinct textures that reflect classic hand crafted flooring. Texturing impacting both the appearance and feel of a floor, texturing is used to bring out unique attributes of different species and stain (applied after) to create a distinctive finished floor. To learn more about these techniques and results click the below link.

Plank Size

For decades, classic 2 ¼” or 3” wide flooring was the US standard, but today wide plank (generally considered 5” to 10”) flooring is the sought-after choice. Wide plank floors are almost universally offered in long average lengths from 4’ to upwards of 8’. Longer lengths give floors an attractive, harmonious appearance by both reducing the total number of end joints as well as spacing adjoining plank’s end joint further apart,

Picking a desired width for a project is an aesthetic choice. While wider options (8”, 9” and 10”) are generally considered to be more luxurious, mid width (5”, 6” and 7”) are often preferred when considering the relative scale of the area being covered (i.e. smaller rooms) or other attributes of the floor.

Color & Finish

Stains, applied to the surface of your flooring are designed to interact with the species, grade, cut and texture to create a distinct color and appearance. Advanced stains achieve the whole spectrum of colors from dramatic dark stains to bright light colored floors. Sealing in and protecting the stain is the finish which offers an invisible layer of protection for your hardwood floors. In remodels, flooring colors will often draw from the color palette of the existing surface and furnishings, while in new builds it may often be an early choice helping define the colors of other elements designed into your home. Designers will often create design palettes (swatches of items in a project including flooring, paint, fabric and more) to see how they appear together. They can then switch out items until they find a desired mix